Unlocking the Potential of Surface Mount Haptics in Modern Electronics

At PUI Audio, we strive to continually push the boundaries of haptic feedback technology. From our 2022 introduction of haptics to the 2023 expansion of our Linear Resonant Actuator (LRA) portfolio, we’ve worked hard to deliver high-quality, efficient haptic devices for modern electronics. Our latest offering—industry’s first surface mount linear haptic actuator—embodies this commitment to innovation. Designed for seamless integration into various industries, it represents a leap forward in tactile feedback technology.

What Is a Surface Mount Haptic Actuator?

A surface mount haptic actuator is an electromechanical device providing tactile or vibrational feedback in response to user interaction. These devices are used in smartphones, gaming consoles, VR environments, and more. What makes this new generation of surface mount actuators unique is their ability to be directly mounted onto PCBs using surface mount technology (SMT). This eliminates manual soldering and wiring, enabling fully automated manufacturing processes.

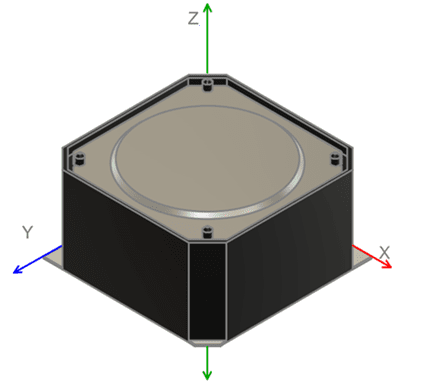

The core components of the actuator include a coil, counterweight mass, and suspension ring, all encased in a durable housing. When alternating current is applied to the coil, a magnetic field forces the counterweight mass to move rapidly, producing vibrations that can be felt as tactile feedback.

Why Choose Surface Mount Technology for Haptics?

Surface mount technology (SMT) is the preferred method for electronics manufacturing due to its automation-friendly process. By using SMT, PUI Audio’s haptic actuators can be soldered directly onto PCBs, just like other electronic components, which streamlines assembly and boosts production efficiency. SMT actuators eliminate the need for adhesives, manual soldering, or external mounting hardware.

The ability to use high-temperature materials in these actuators ensures they withstand the reflow soldering process, where temperatures can reach between 240°C and 260°C. The parts are packaged in tape and reel, making them ideal for automated pick-and-place machines.

Advantages of Linear Resonant Actuators

Linear Resonant Actuators (LRA) offer numerous benefits compared to other haptic technologies, such as Eccentric Rotating Mass (ERM) devices. LRAs provide a more immediate tactile response, with no ramping time to reach full actuation. This makes them ideal for applications where high-resolution feedback is necessary, like wearables and smartphones.

LRAs are driven by AC signals and produce vibrations along a single axis, typically the Z-axis. Their power efficiency and small form factor make them the preferred choice for designers aiming to deliver precise and responsive haptic feedback.

Implementing Drive Circuits for Haptic Devices

To drive a surface mount linear haptic actuator, two options exist:

- Custom Drive Circuit: Using discrete components such as MOSFETs in a PWM-controlled H-Bridge circuit.

- Integrated Driver System: A more streamlined approach involves using an IC chip, which handles everything from auto-resonance detection to vibration pattern control. These integrated systems often feature pre-programmed libraries, making them easier to implement.

PUI Audio recommends partnering with our engineering team to select the optimal drive system for your application.

Frequently Asked Questions

- Maximizing Vibration Intensity: Operate the actuator at its resonant frequency and modify the drive signal amplitude for optimal control.

- IC Options for Haptics: We recommend Texas Instruments’ DRV2605L or Maxims’ MAX1749, among others, for a seamless integration of haptic feedback with your device.

- LRA vs. ERM: LRA provides higher resolution feedback, while ERM offers a higher-frequency rumble, making each suitable for different applications.

Compact & Precise For Your Application

PUI Audio’s surface mount linear haptic actuator HD-LA1307 offers high-quality, precision tactile feedback for a wide range of applications, from medical devices to consumer electronics. Their compact size, power efficiency, and seamless integration into automated manufacturing processes make them a top choice for modern product designs.

For more information or to explore custom solutions tailored to your project, contact us via our contact form. Let PUI Audio help you bring your haptic feedback needs to life.