Enhance Your Security with Precision: A Deep Dive into the PSD0401120

Overview: MEMS Sensors in Modern Security

In the ever-evolving world of security technology, precision and reliability are crucial. The PSD0401120 MEMS pressure sensor from PUI Audio stands out for its ability to deliver both, making it an essential component in advanced security systems. From detecting subtle air pressure changes to integrating seamlessly with other sensors, this sensor is engineered to provide accurate and timely responses to environmental shifts.

Application in Security Systems

Detecting Air Pressure Changes

One of the key roles of the PSD0401120 in security systems is detecting air pressure variations within a defined space. Even minor changes in air pressure can signal events such as:

- Opening or closing doors and windows

- Glass breakage (indicating potential intrusion)

- Movement within a room (altering the ambient air pressure)

By capturing these variations, the sensor can alert the system to unauthorized entry or other suspicious activities.

The Power of Integration: Multiple Sensors for Enhanced Accuracy

In a typical security setup, MEMS pressure sensors like the PSD0401120 can be combined with other sensor types, such as microphones and motion detectors, to enhance the system’s sensitivity and accuracy. This integration allows for:

- Enhanced Detection Accuracy: By correlating pressure changes with acoustic events (e.g., glass breaking), the system can better distinguish between normal and suspicious activities.

- Minimized False Alarms: Cross-referencing data from multiple sensors reduces the likelihood of false triggers, ensuring that alerts are more accurate.

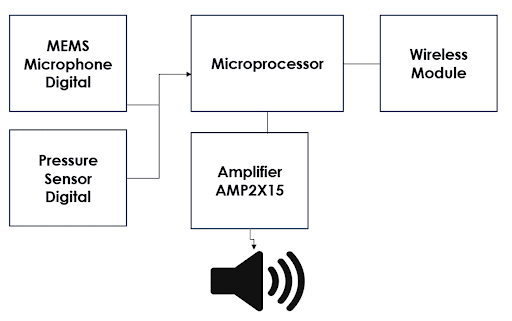

The Role of Microcontrollers and Sensors

To make the most of the PSD0401120’s data, a robust microcontroller is essential. Microcontrollers like the ESP32 provide ample I/O flexibility, making them ideal for handling the sensor’s I2C data stream while integrating it with other components in the system. With built-in Wi-Fi and Bluetooth capabilities, microcontrollers ensure that any detected security breach is promptly communicated to the central monitoring system.

Workflow Overview

- Event Detection:

- The PSD0401120 pressure sensor senses air pressure changes in real time.

- Microphones capture the acoustic signature of events, such as glass breaking.

- Data Processing:

- A microcontroller analyzes the data, using programmed algorithms to detect patterns and anomalies.

- Event Classification and Response:

- If an abnormal event is detected (e.g., an intrusion), the system triggers a response like sounding an alarm or sending a notification via speaker solution.

- Alert Transmission:

- Using built-in wireless modules, the system sends alerts and relevant data to a monitoring service or the end user’s device.

Tailored Solutions for Unique Requirements

The PSD0401120 can be customized to meet the unique needs of different security applications. Its high sensitivity and low power consumption make it ideal for battery-operated systems, while the compact design ensures it can fit into tight spaces.

Conclusion: The Right Sensor for Advanced Security

With the PSD0401120, PUI Audio offers a versatile and powerful solution for modern security needs. By leveraging precise air pressure detection and seamless integration with other sensor technologies, it helps ensure comprehensive and reliable monitoring. Whether you are designing a home security system or an industrial surveillance setup, this sensor can elevate your project to the next level.

Interested in exploring custom solutions for your security needs? Get in touch through our Contact Form to learn more or discuss how the PSD0401120 can enhance your next project.